Information

Cost Accounting - Merchandising vs Manufacturing

Basic shortcuts

| Ctrl + S | Save subtitles |

|---|---|

| Ctrl + click Double click | Edit highlighted caption |

| Tab | Edit next caption |

| Shift + Tab | Edit previous caption |

| Esc | Leave edit mode |

| Ctrl + Space | Play / pause video |

| Ctrl + Home | Play selected caption |

| Ctrl + Enter | Split caption at cursor position at current time |

Advanced shortcuts

| Ctrl + Insert | Add new caption |

|---|---|

| Ctrl + Delete | Delete selected caption |

| Ctrl + I | Edit currently played segment |

| Shift + Enter | New line when editing |

| Ctrl + Left | Play from -1s |

| Ctrl + Right | Play from +1s |

| Alt + Left | Shift caption start time -0.1s |

| Alt + Right | Shift caption start time +0.1s |

| Alt + Down | Shift caption end time -0.1s |

| Alt + Up | Shift caption end time +0.1s |

Annotation shortcuts

| Ctrl + 1 | Hesitation |

|---|---|

| Ctrl + 2 | Speaker noise |

| Ctrl + 3 | Background noise |

| Ctrl + 4 | Unknown word |

| Ctrl + 5 | Wrong segment |

| Ctrl + 6 | Crosstalk segment |

00:00.0

00:23.3

00:23.3

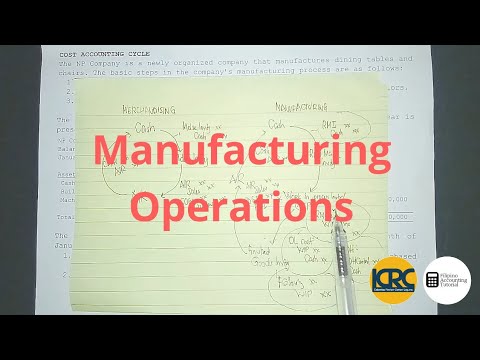

Cost Accounting Cycle, so bago tayo magproceed sa problem solving under Cost Accounting Cycle, pagkumparahin muna natin yung operating cycle ng merchandising at manufacturing.

00:34.0

00:50.5

00:50.5

Sa operating cycle ng Merchandising... Basically kapag merchandising-buy and sell. Bibili ng inventory, then ibebenta sa customers.

00:50.6

01:27.7

01:27.7

So start at cash then yung cash gagamitin pambili ng merchandise inventory so to record yung acquisition ng merchandise inventory, debit merchandise inventory, credit cash.

01:27.8

01:43.2

01:43.2

Then itong merchandise inventory na ito is yung inventory na ibebenta sa customers (symbolized by A/R)

01:43.3

01:58.4

01:58.4

So to record yung sale ng inventory to customers, debit A/R, credit Sales. And debit COGS and credit merchandise inventory.

02:32.3

02:43.9

02:43.9

Kapag merchandising, yung inventory na binebenta mo sa customers mo is binibili mo lang siya. Kumbaga buy inventory and sell inventory.

02:44.0

03:06.5

03:06.5

Kapag manufacturing, yung inventory na binebenta mo sa customers mo is ikaw mismo yung gumagawa- ikaw mismo yung bumubuo ng inventory. Ikaw mismo yung gumagawa ng product na imamanifacture mo sa customers mo.

03:06.6

03:40.2

03:40.2

So yung operating cycle ng manufacturing- so start ulit tayo sa Cash. Then yung cash na yon is- siyempre para makabuo/manufacture ka ng product is kakailanganin mo ng inventory-yung tinatawag na raw materials inventory.

03:40.3

04:01.7

04:01.7

So to record the acquisition of raw materials, debit Raw Materials Inventory,credit Cash.

04:01.8

04:50.1

04:50.1

Siyempre yung raw materials mo, yan ay gagamitin mo para makabuo ka ng product so yung raw materials inventory mo malilipat na siya sa tinatawag na Work in process Inventory/Goods in Process.

04:50.2

04:59.5

04:59.5

So ano ba yung mga kailangan mo para makabuo ka ng product? Siyempre kailangan mo ng raw materials.

04:59.6

05:15.3

05:15.3

So to record yung transfer ng raw materials para makabuo ka ng product which is dadaan muna siya sa work in process is debit Work in Process, credit Raw Materials Inventory.

06:35.4

07:06.3

07:06.3

Siyempre, kailangan mo rin yung tinatawag nating Factory Overhead (FOH) wherein ito yung mga cost na related sa pagmamanufacture ng product mo which is hindi siya under ng raw materials at hindi direct labor.

07:06.4

07:23.9

07:23.9

So to record yung Factory Overhead, debit Factory Overhead Control, credit Cash or any appropriate account.

07:43.3

07:57.3

07:57.3

Siyempre yung Work in Process mo magiging finish goods yan-matatapos yan sa lahat ng proseso na kailangan para makabuo ko ng product.

07:57.4

08:24.0

08:24.0

So yung work in process mo, magiging finish goods. Kung 100% tapos na yung product, mapupunta siya sa Finished Goods Inventory.

08:24.1

08:56.4

08:56.4

So to record yung pagtransfer ng inventory from Work in Process to Finished Goods, debit Finished Goods Inventory, credit Work in Process- mababawasan yung Work In Process.

08:56.5

09:03.2

09:03.2

Itong "Finished Goods Inventory" yung ibebenta na sa mga customers mo. So itong Finished Goods Inventory magiging A/R.